Product description:

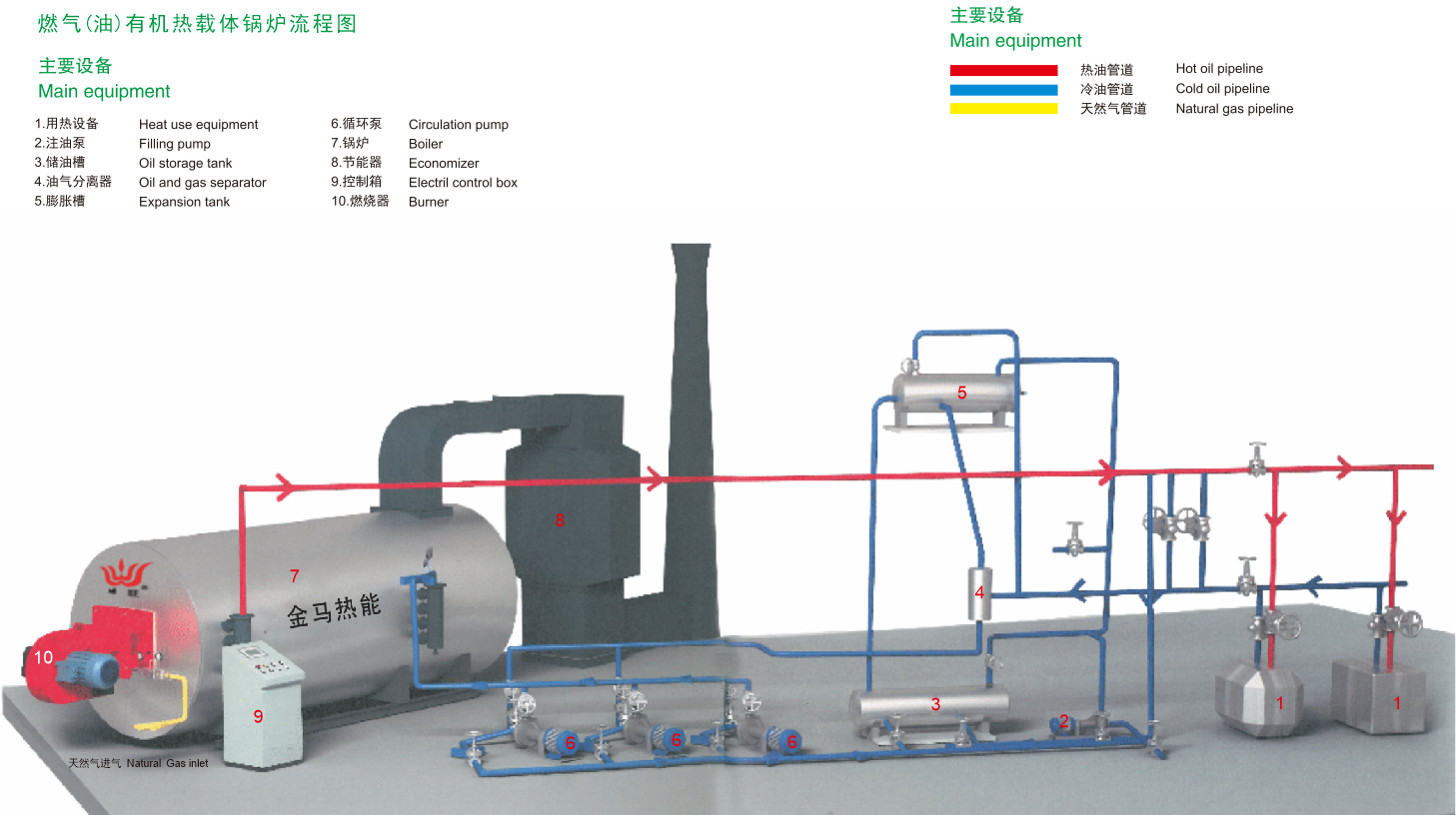

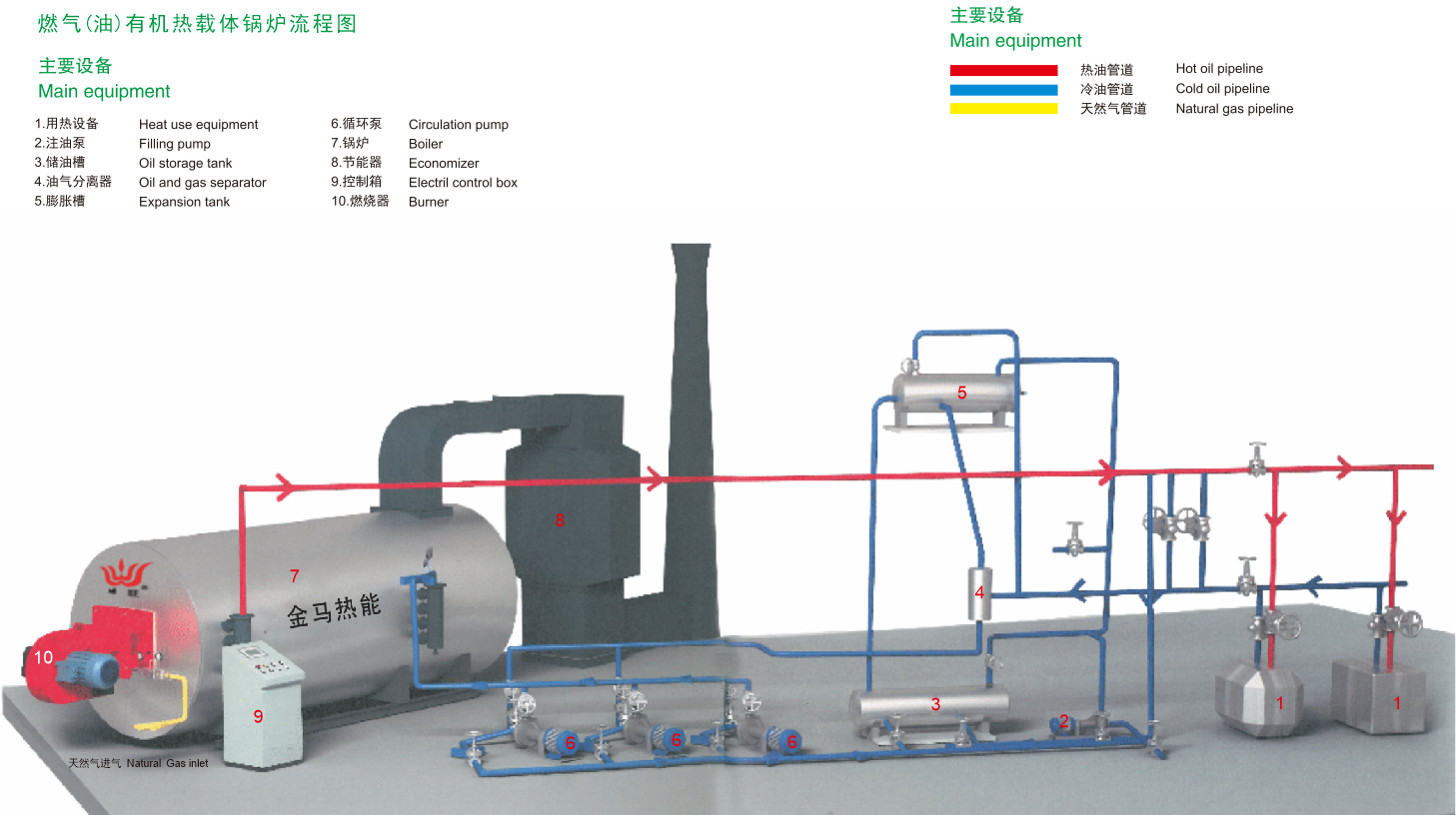

The organic heat carrier boiler is a once-through special boiler developed based on the design thinking of forced circulation. The closed loop heating is connected to the atmosphere to prolong the service life of the boiler, the heat loss of liquid phase transportation is small, the energy saving effect is significant, and the environmental protection effect is good.

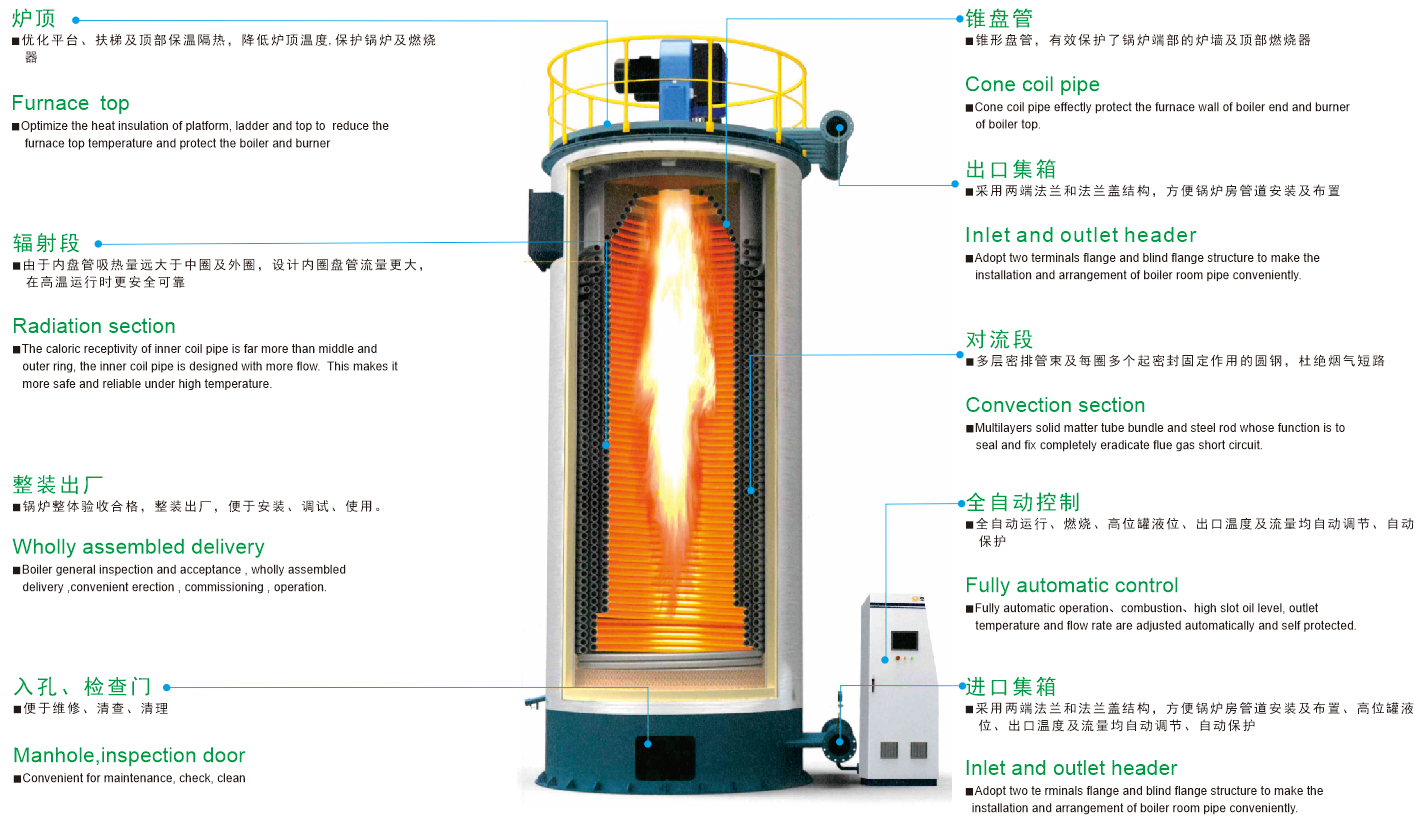

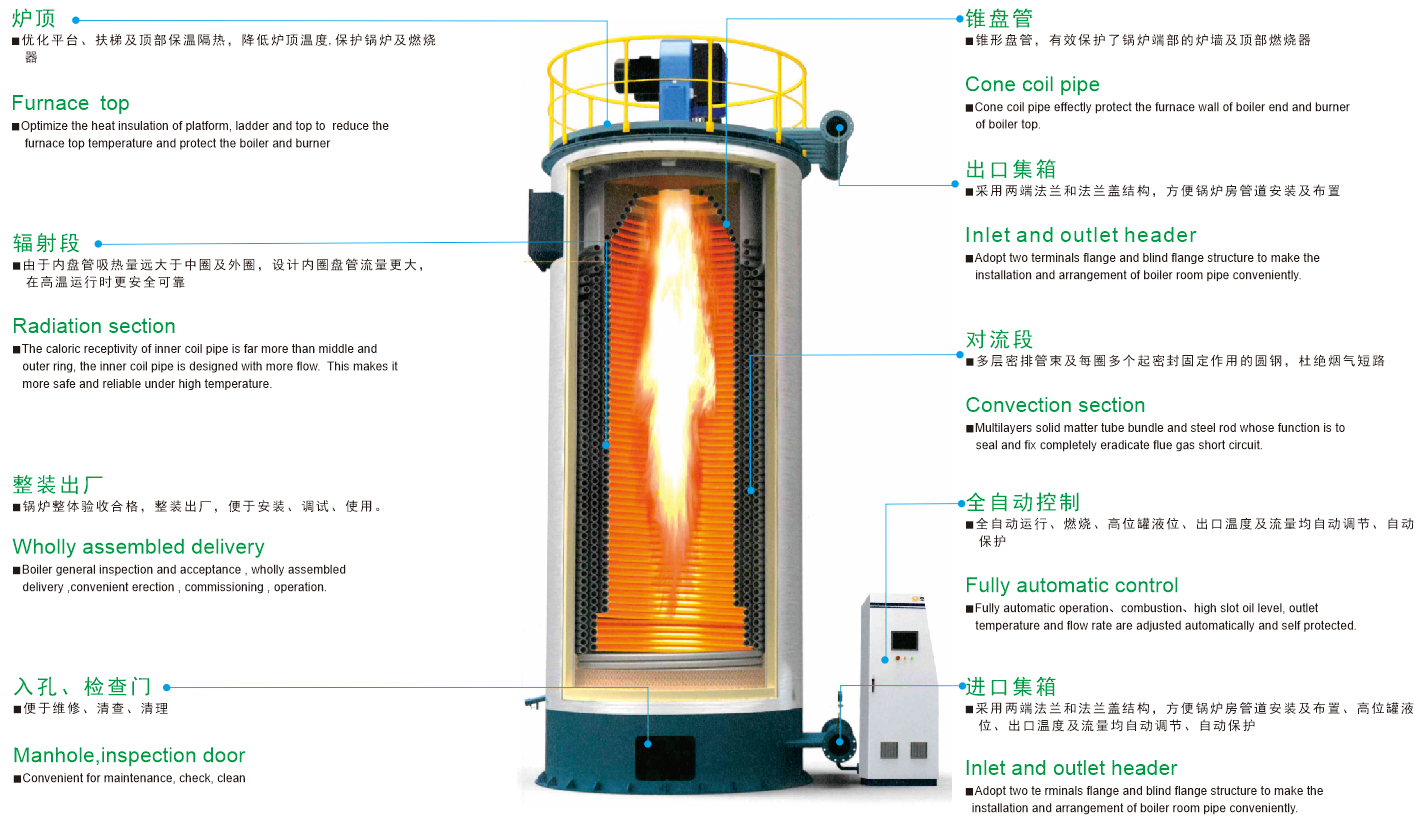

The body adopts a flue gas three-pass coil design. This direct-flow structure solves the problem of poor safety of traditional boilers. Due to the coil structure, the heating surface is sufficient, which makes it have high thermal efficiency. The remarkable feature of the organic heat carrier boiler is that the countercurrent heat exchange, the temperature difference between the combustion exhaust gas temperature and the heat conduction oil outlet temperature is below 30°C. The excellent structure of the organic heat carrier boiler is mainly to operate at a lower pressure, and the operating temperature below 450 ℃ has the characteristics of low pressure and high temperature.

1. Original imported burner 2. Labyrinth double-sealed front and rear movable aluminum box doors 3. High thermal resistance insulation materials and inner and outer protective plates 4. Three-pass flue gas coil design 5. Closed circulating heating 6. Large furnace tank, high Radiating surface

Features:

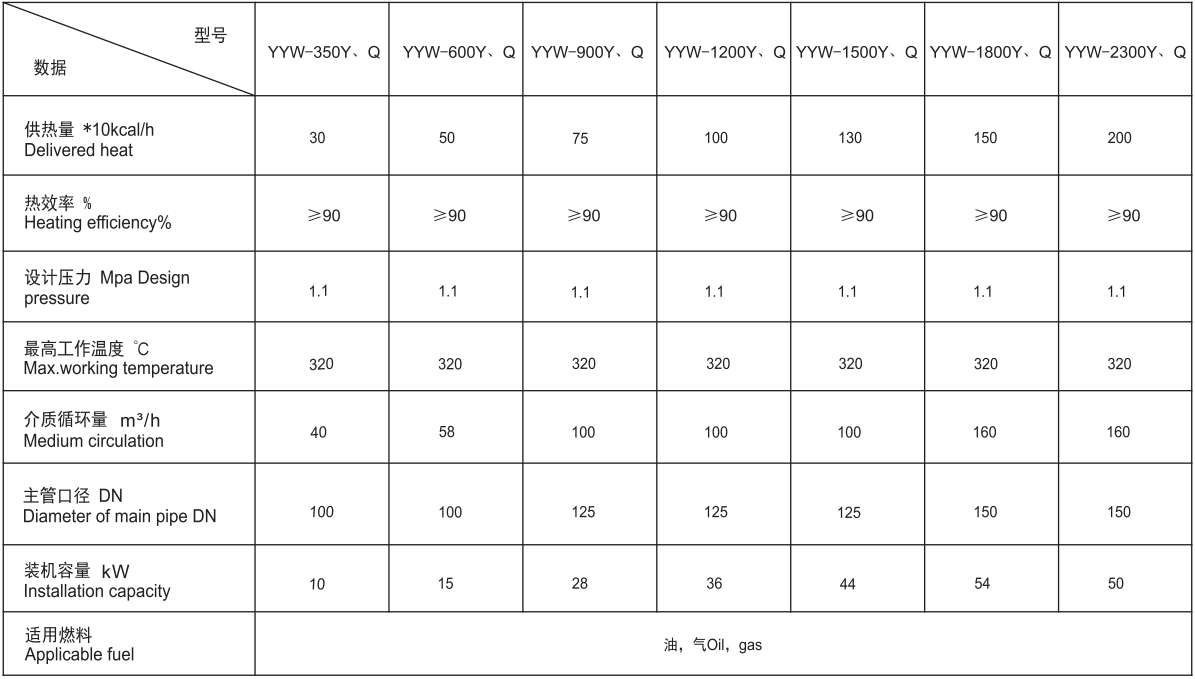

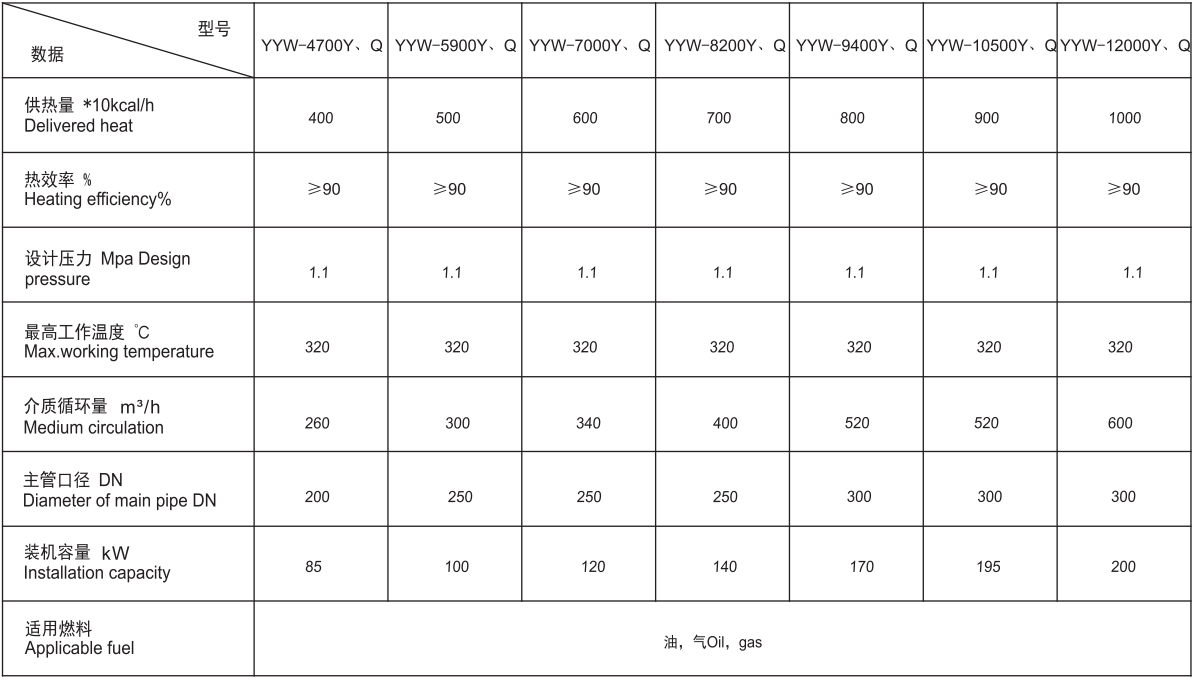

Heat supply: 180-35000kW

Furnace type: horizontal

Fuel: light oil, heavy oil, residual oil, natural gas, coal gas

Technical features: Optimized design of overload heating

Double or multi-layer coil and sheet coil structure

Space thermal intensity optimization and enhanced convection heat transfer technology Quick opening furnace body structure

Automatic reset technology of explosion-proof door

Automatic optimization control technology

Low NOx combustion and environmental protection control technology

Strengthen insulation technology

Thermal efficiency maximization technology

Current location:

Current location: