Features:

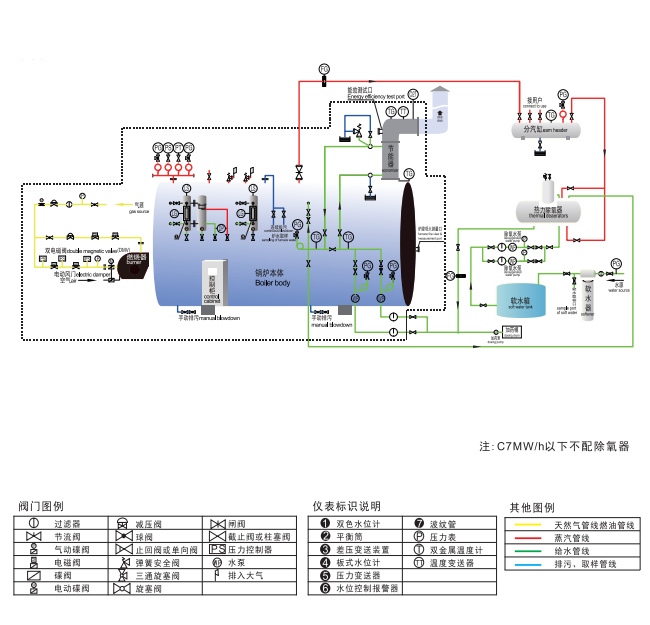

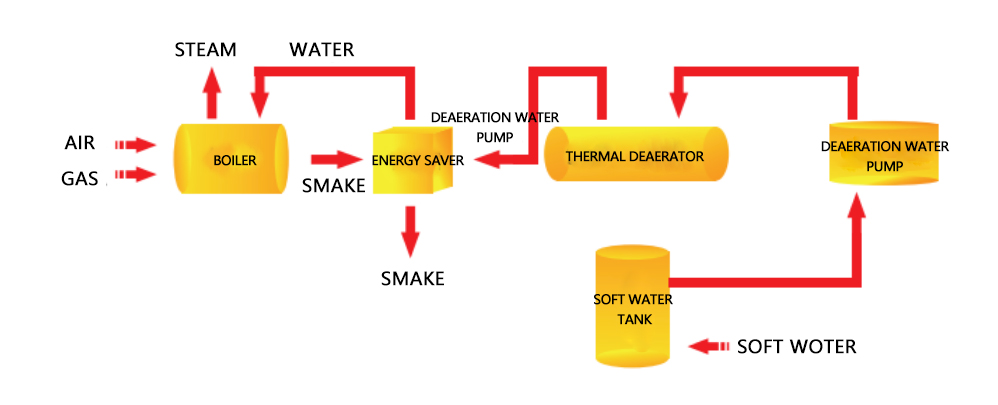

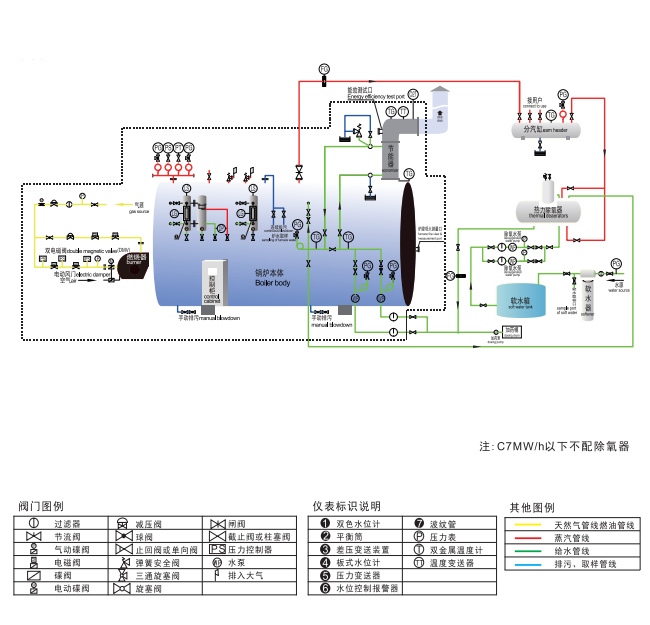

The wet-back three-pass structure is adopted, and the flue pipes are symmetrical and evenly distributed on the furnace tube axis, which can improve the stress distribution of the tube sheet. The wet-back structure of the combustion chamber is completely immersed in water, with good cooling conditions, and the rear tube sheet is not washed by high-temperature flue gas. ,long lasting. The application of the corrugated furnace not only increases the heating surface but also alleviates the possible damage to the combustion chamber due to thermal expansion and contraction, and increases the temperature. Large furnace volume combustion completely saves fuel. The front smoke box adopts a hinged connection, which can be easily opened with double-layer heat insulation, which not only reduces the temperature of the front panel but also improves the thermal efficiency. The large steam space keeps the steam out of the water at a low speed and the built-in steam-water separation device ensures a stable output of high-quality steam. The use of threaded smoke tubes enhances the heat exchange effect and improves the thermal efficiency. The application of advanced digital control technology can accurately monitor the combustion process remotely, with high degree of automation, complete various protections, and automatic control of water level and pressure. An energy-saving heat exchanger can be added to the smoke outlet to reduce the exhaust gas temperature and absorb the sensible heat and latent heat in the flue gas, and improve the efficiency of the boiler (up to 96%).

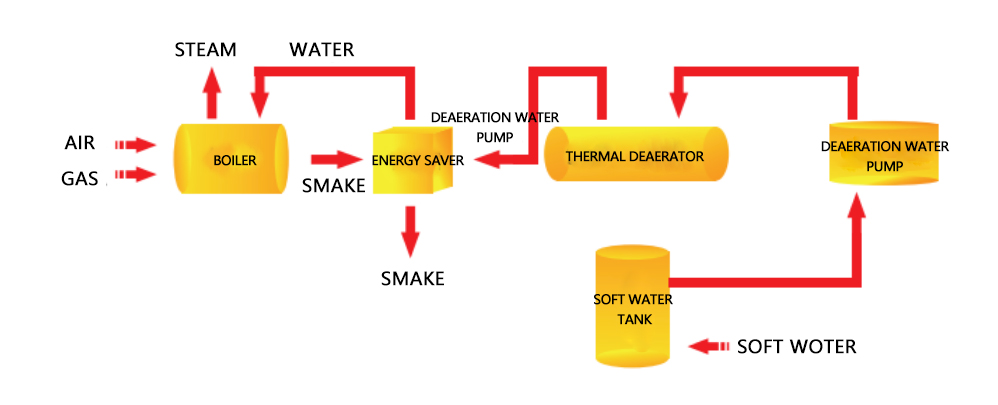

Installation diagram:

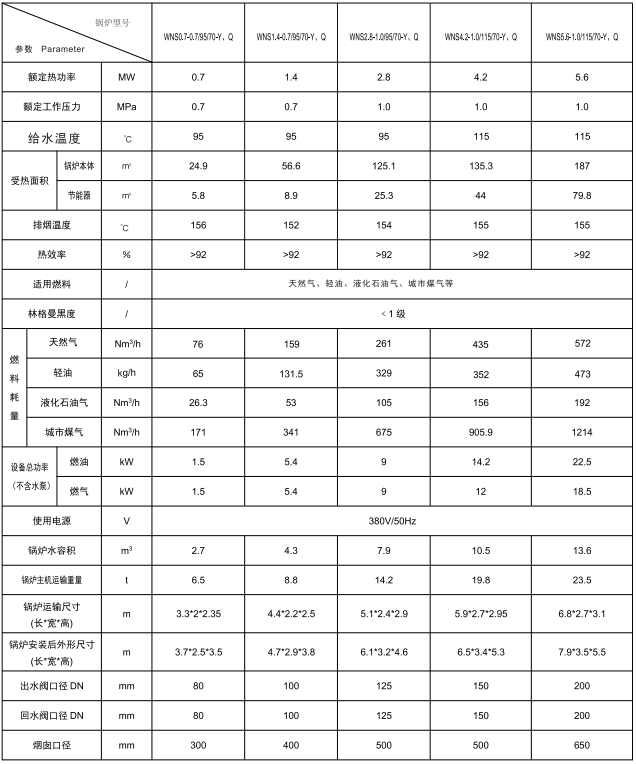

Current location:

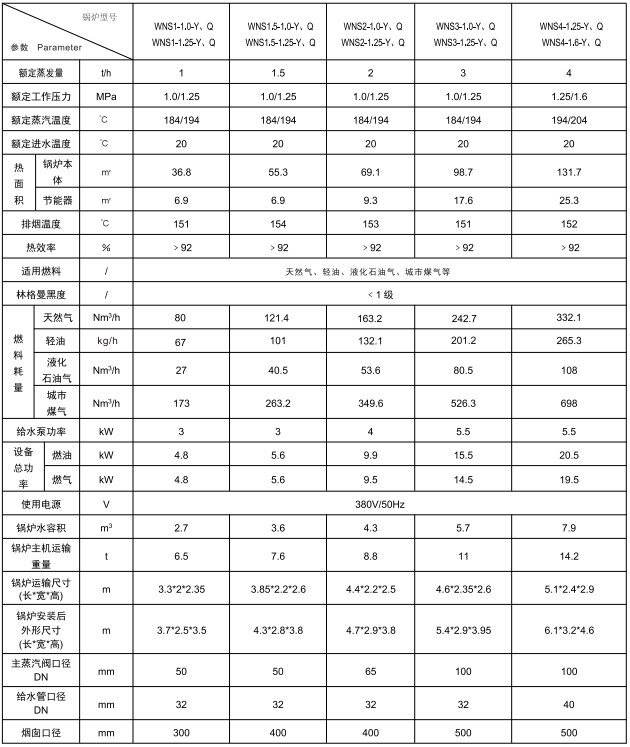

Current location: