WNS type condensing boiler is based on the analysis and summary of the relationship between the condensation rate of water vapor in the flue gas and the exhaust gas temperature, the relationship between the condensation rate and thermal efficiency, and the corrosion rate of condensed water on different steel grades, and the reasonable design of the heating surface A condensing boiler that greatly reduces the exhaust gas temperature to ensure that the water vapor in the flue gas reaches the condensation rate required by the design, absorbs and utilizes the sensible heat in the flue gas and the latent heat of vaporization released during the condensation process of the water vapor, thereby greatly improving the thermal efficiency of the boiler

working principle

The exhaust gas temperature is the basic parameter of the boiler. Choosing a lower exhaust gas temperature can reduce the exhaust gas loss of the boiler and help improve the thermal efficiency of the boiler. If the exhaust gas temperature of the boiler drops to a sufficiently low level, the superheated water vapor in the flue gas will condense and release the latent heat of vaporization

Performance characteristics

1 The energy saving effect is very significant. Calculated based on the low calorific value of the fuel, the thermal efficiency exceeds 100%

2. More environmentally friendly. Harmful components in the flue gas dissolve in the condensed water, effectively reducing emissions and improving emission indicators

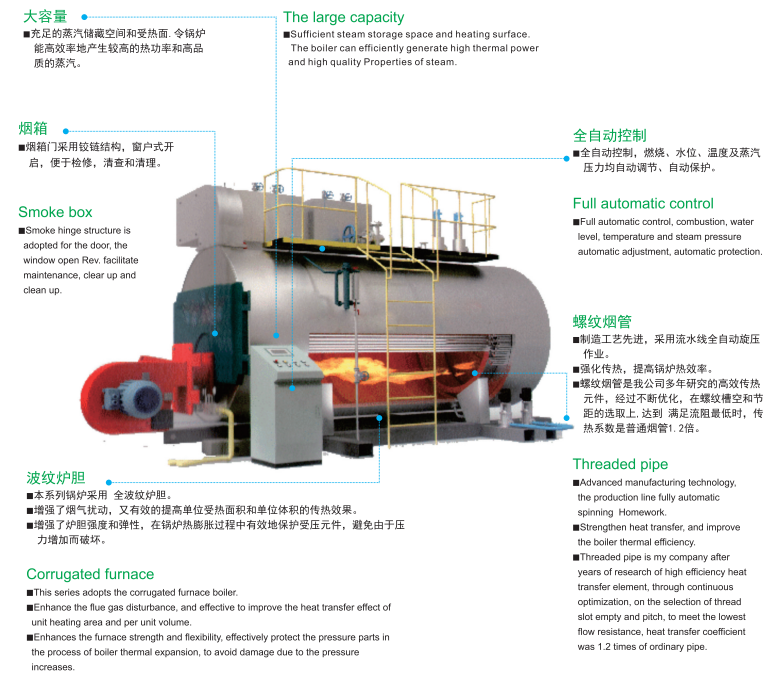

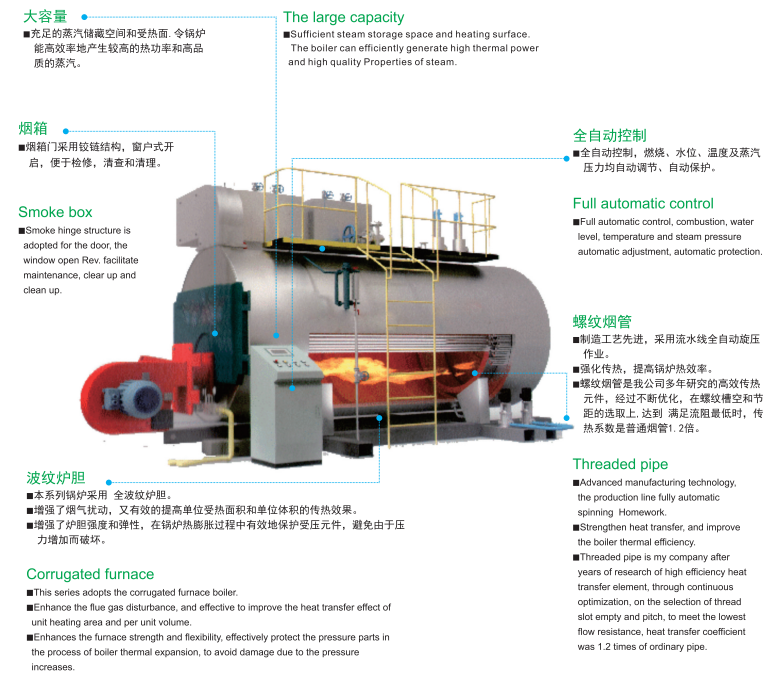

Boiler manufacturing process

The key processing techniques such as steel plate blanking, rolling, tube sheet drilling, etc. all adopt advanced numerical control processing techniques to reduce assembly stress and prolong the service life of the boiler. Front and rear smoke box panels are cut by CNC plasma cutting machine, neat and beautiful.

Boiler welding process

Both longitudinal and circumferential seam welding of the boiler adopts advanced submerged arc automatic welding technology to ensure welding quality. All longitudinal and circumferential welds are subjected to 100% radiographic inspection. The welding of the smoke pipe and the tube sheet adopts pre-expansion to eliminate the gap between the tube and the tube sheet, and then adopts the welding process of argon arc welding. Welding effectively eliminates stress and prolongs the service life of the boiler.

Furnace insulation

The furnace body is made of high-quality aluminum silicate fiber, and refractory mud is used for heat preservation. The temperature of the furnace body is controlled below 45 degrees to effectively control the heat loss. The front and rear smoke boxes are filled with multilayer aluminum silicate fibers, and then insulated with high-temperature refractory mud to increase thermal resistance, effectively reduce heat dissipation loss and improve thermal efficiency.

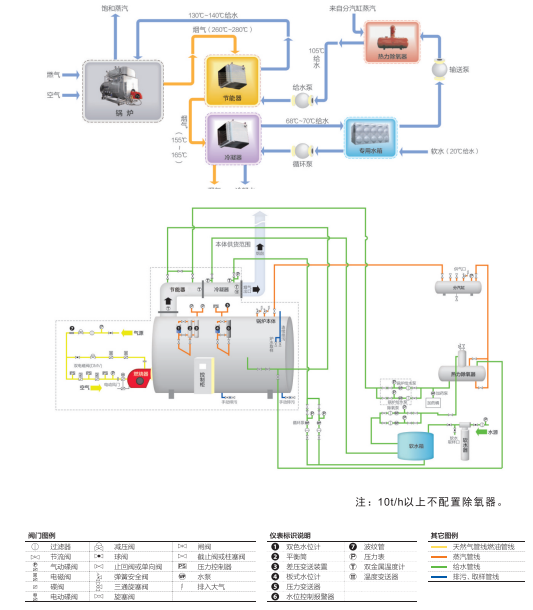

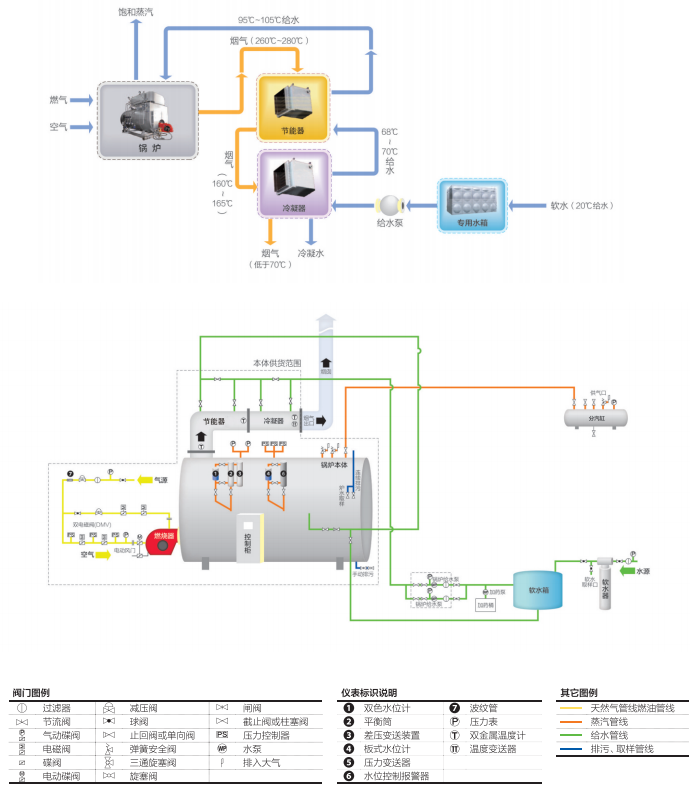

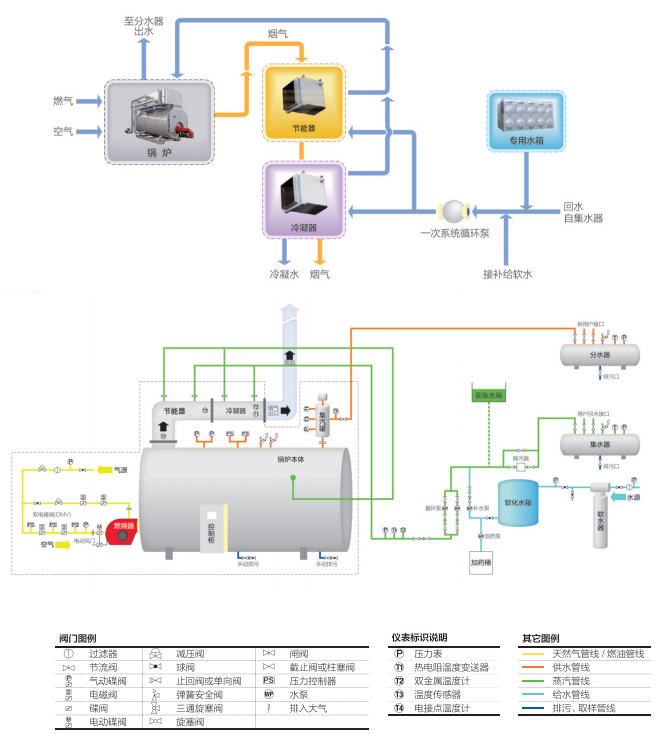

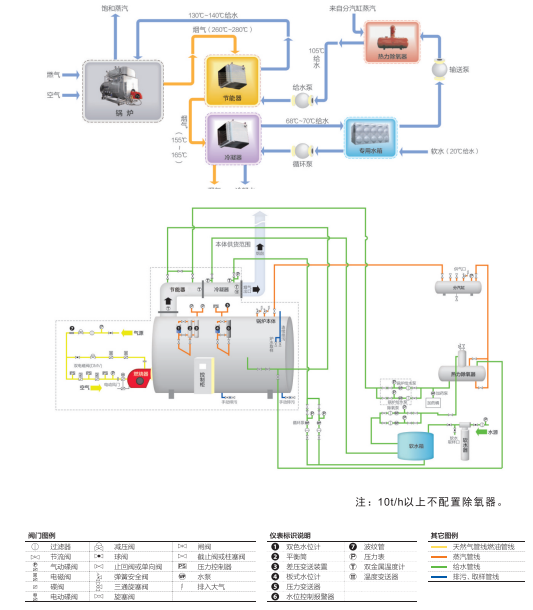

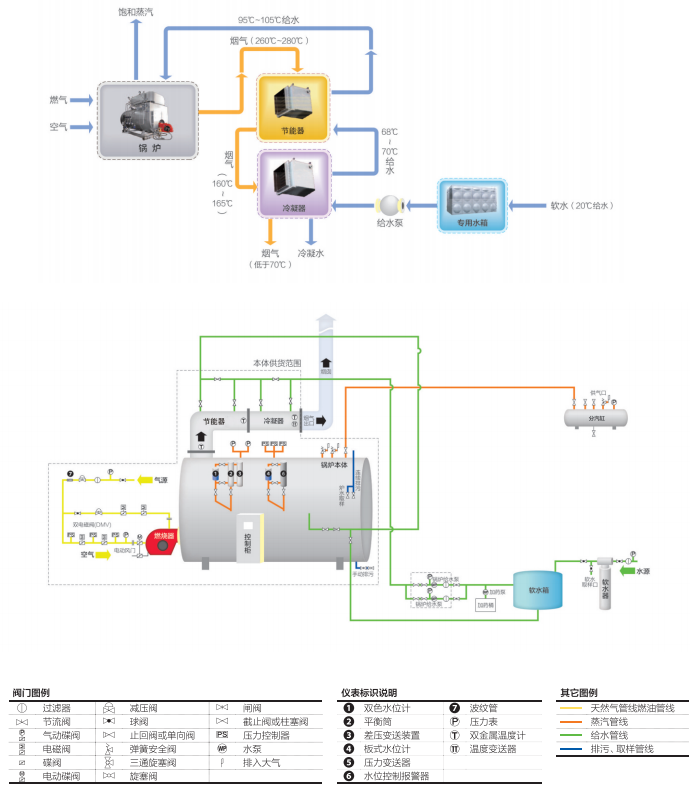

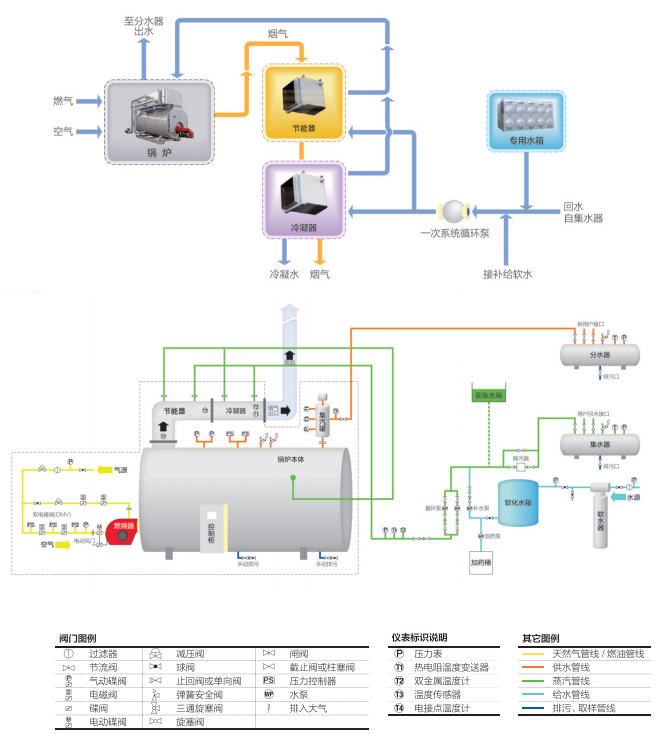

WNS condensing gas (oil) boiler system diagram

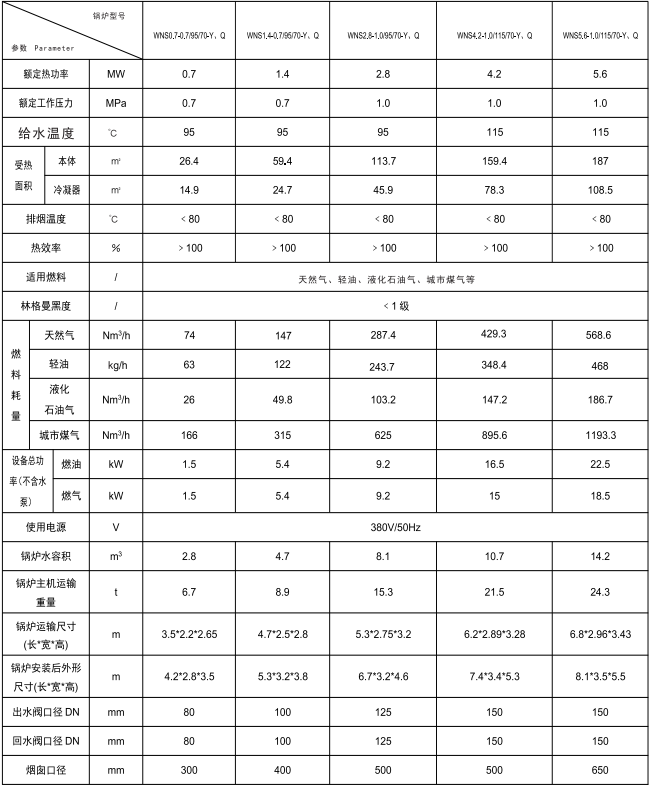

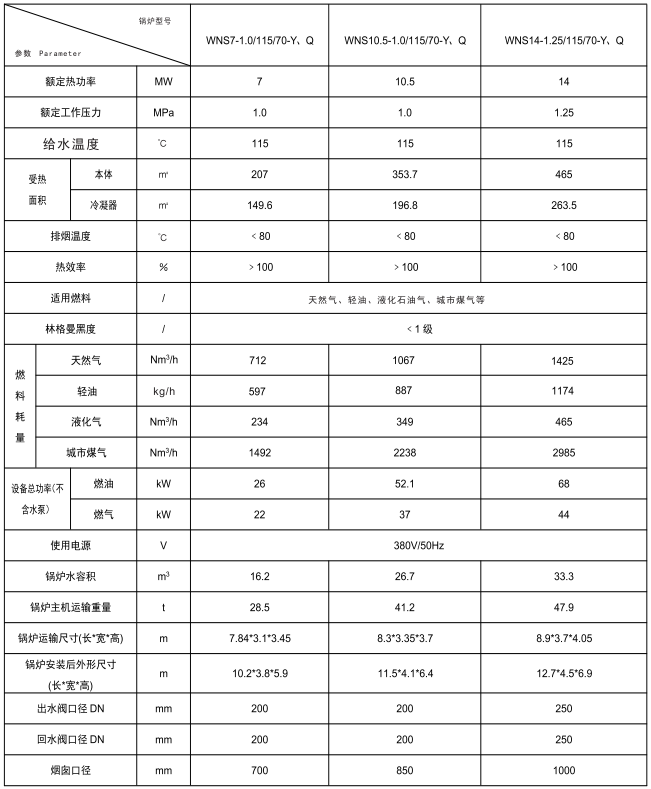

Deaeration water supply mode (105℃ water supply)

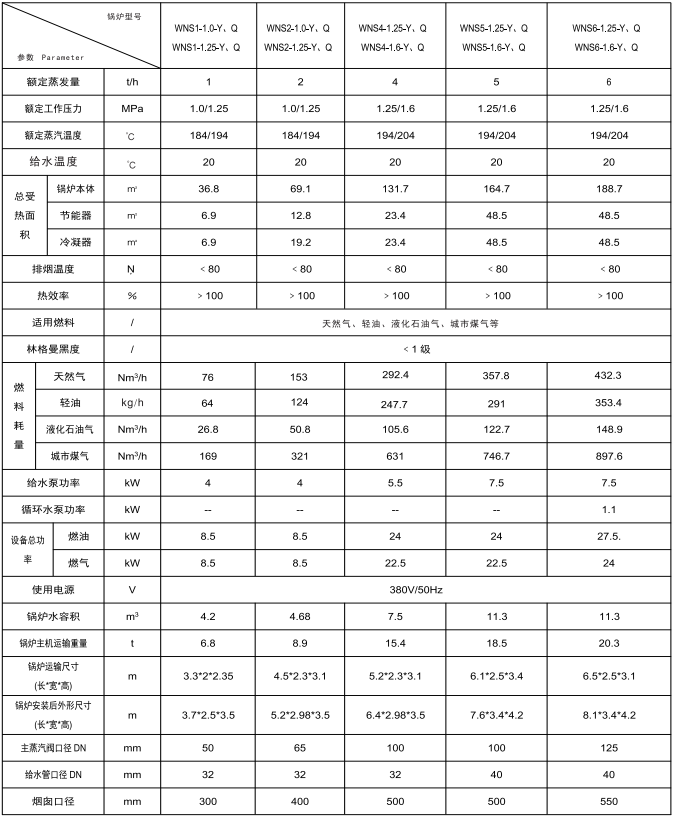

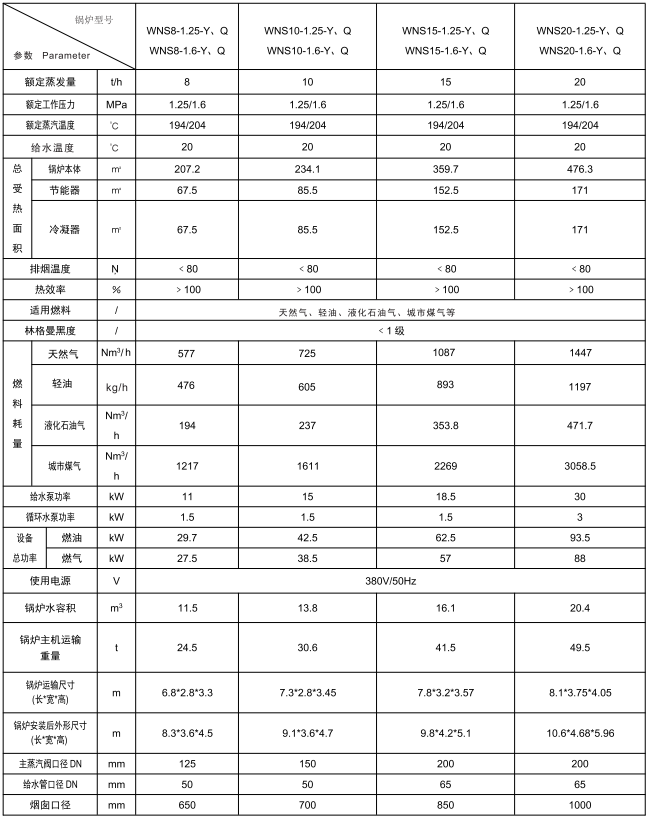

Direct feed water mode (feed water at 20 ℃)

Boiler system

Current location:

Current location: