Garbage incinerator

Realize waste disposal on the spot to achieve the best effect of harmless and reduced waste disposal

Contact wechat

Contact wechat

24-hour Information Hotline:

0519-86701064

24-hour Information Hotline:

0519-86701064

Current location:

Home>Product Center>Boiler

Current location:

Home>Product Center>Boiler

Realize waste disposal on the spot to achieve the best effect of harmless and reduced waste disposal

1. Thoroughly eliminate the conditions for the formation of dioxin, take multiple measures to ensure that the flue gas of the second combustion chamber stays above 850 degrees for more than 2 seconds, and adopt a downstream economizer quench device

2. The heat energy is fully utilized and the harmless reduction rate is more than 95%. The furnace body adopts a vertical layered design, so that the garbage is dried, gasified, carbonized, etc. in sequence

3. There is no need to add any auxiliary fuel for primary combustion. The complementary combustion principle of pyrolysis, gasification and carbonization is scientific and reasonable, and it is suitable for domestic waste without complex pretreatment.

4. High degree of automation, programmable operation, one key to press fire, one key to start, adapt to the fluctuation of daily garbage collection

5. Integrate traditional furnace body production and manufacturing experience, equipment structure insulation, furnace body pouring, professional and reliable selection of grate production

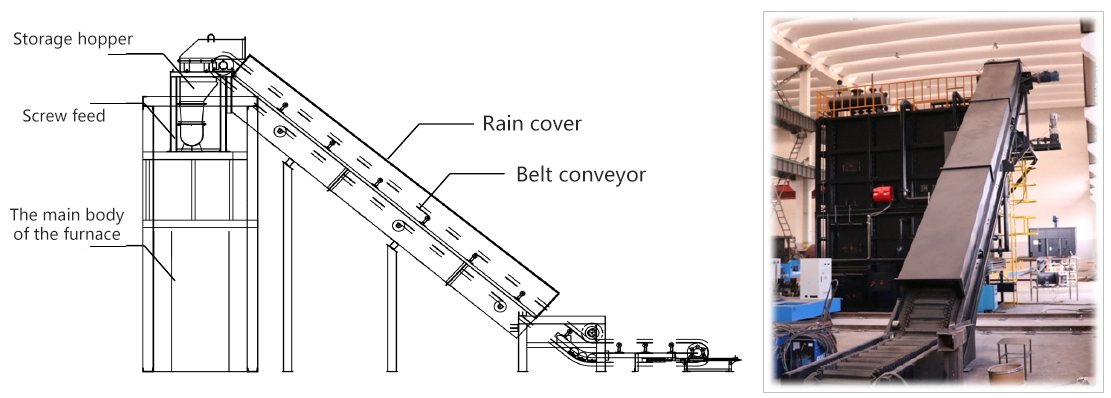

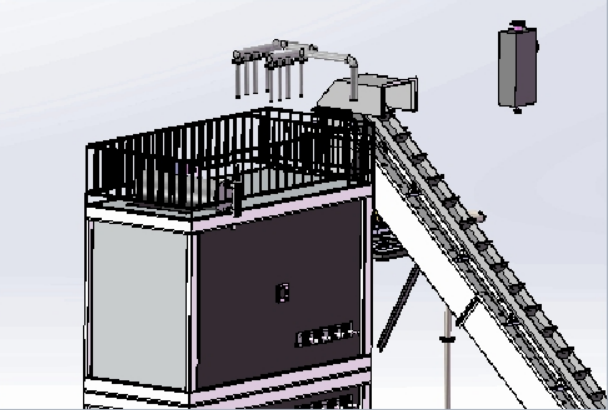

1. Feeding and conveying subsystem

(1) Continuous supply of garbage to ensure the continuity of furnace operation;

(2) Form a material seal to ensure that the flue gas overflows (or air flows in);

(3) Belt feeding and shaftless spiral feeding are in line with garbage characteristics and prevent material jams;

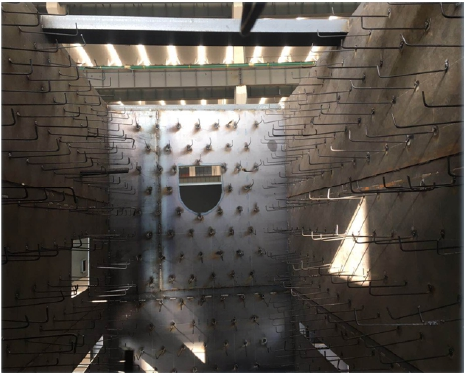

2. Furnace wall system

The FTL furnace wall structure is divided into a drying furnace layer, a gasification and carbonization furnace layer, a combustion chamber, and a second combustion chamber; the furnace body is vertically distributed, and the whole layer of the furnace wall is casted at 350mm, including a three-layer structure of heat resistance, heat insulation and heat preservation.

(1) Ensure that the heat in the furnace is not lost;

(2) Ensure that the temperature outside the furnace meets the human sensory temperature requirements (no heat sensation);

(3) Strong integrity, firm structure and long life;

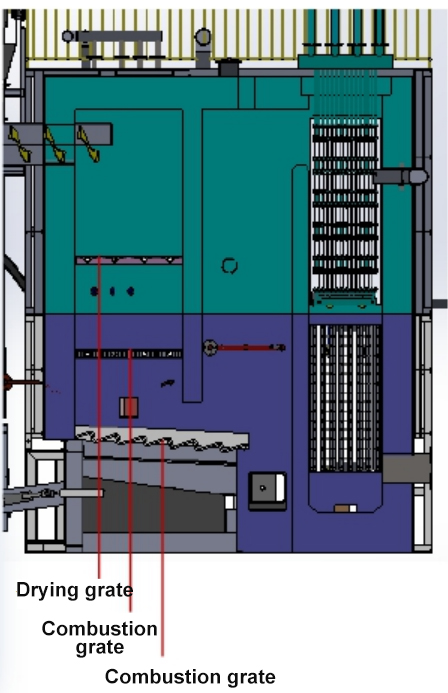

3. Grate system

Drying grate: 1. The grate on both sides of the orifice plate prevents garbage from clogging and unloading. 2. The upward hot air acts together with the heat radiation in the furnace through the long holes to achieve garbage drying 3. Through the grate 4. Realize online automatic control

Carbonization grate: 1. Vertical grate slices, with large gaps between grate slices, which is conducive to the formation of turbulence of high-temperature flue gas and improve the drying effect. 2. Finishing the feeding through the 90° rotation of the grate shaft 3. Realizes online automatic control

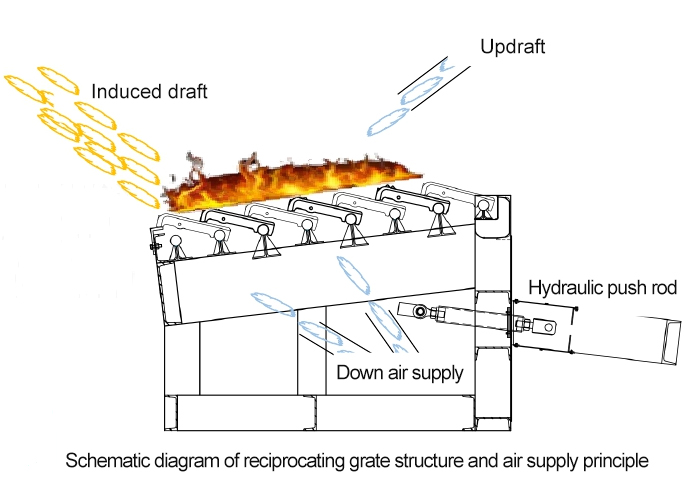

Combustion grate: 1. Reciprocating grate, intermittent movement to ensure full combustion of garbage 2. Air supply on both sides to ensure the looseness of garbage, increase the contact area between garbage and air, and burn more fully 3. Realize online automatic control

4. Air supply subsystem

The air supply volume is an important parameter and guaranteed value for garbage combustion. Controlling the air supply volume is very important to the combustion conditions of the furnace:

(1) Provide oxygen required for combustion, ensure a certain value of excess air (take 1.3), and make garbage fully burned;

(2) Excessive air supply will easily cause heat loss, and will also increase the amount of smoke at the tail end and increase the bag load;

Combustion grate air supply → blower → ambient air → supplementary oxygen → oxygen-enriched combustion

The circulating air circulates the high temperature flue gas to the carbonization grate, its function:

(1) Under the condition of ensuring the balance of gas in the furnace, realize the recycling of heat

(2) The high-temperature flue gas above 600 can also ensure that the garbage is more fully carbonized and reduce the carbonization time

Carbonization grate air supply → circulating fan → high temperature flue gas circulation → heat utilization → evaporation and drying

5. Burning grate

The cooperation between the action form of the reciprocating grate and the frequency conversion control of the blower and the induced draft fan is the key to the stable combustion of garbage, which ensures the combustion oxygen demand and the negative pressure conditions in the furnace:

(1) The action form of the reciprocating grate is an intermittent movement of "1, 3, 5; 2, 4, 6";

(2) The induced air volume is greater than the total air supply volume, so that a negative pressure is formed in the furnace;

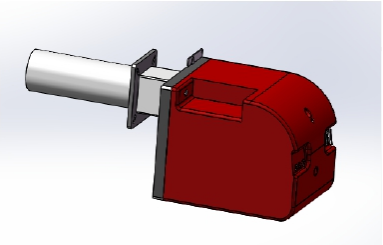

6. Burner system

The burner is the northern part of the second combustion chamber of the FTL furnace body. When the combustion temperature of the second combustion chamber is lower than 850°C, the burner will automatically inject oil to ensure that the combustion temperature of the second combustion chamber is ≥850°C to ensure the removal of dioxin . Second combustion chamber ≥850℃, residence time ≥2s (3.8s), negative pressure windward device, oxygen-enriched combustion state.

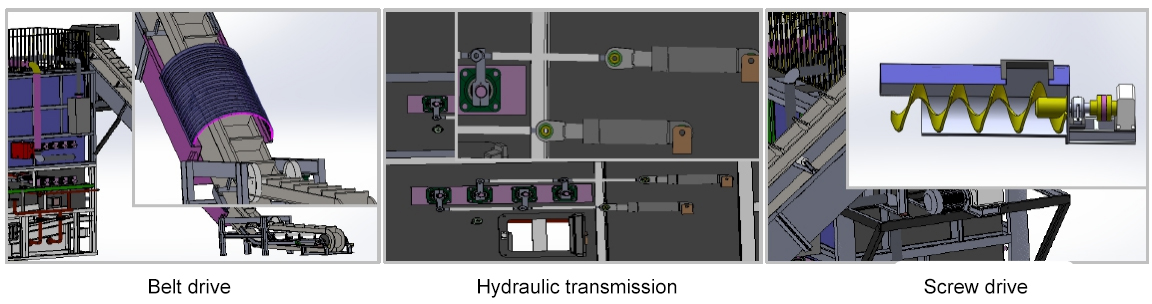

7. Transmission function

The FTL gasifier adopts a transmission system to realize the power operation of belt conveying, feed bolts, drying grate, carbonization grate, and combustion grate, and operates safely and effectively in the automatic control system, and realizes the mutual driving and mutual driving of each power function area. Orderly.

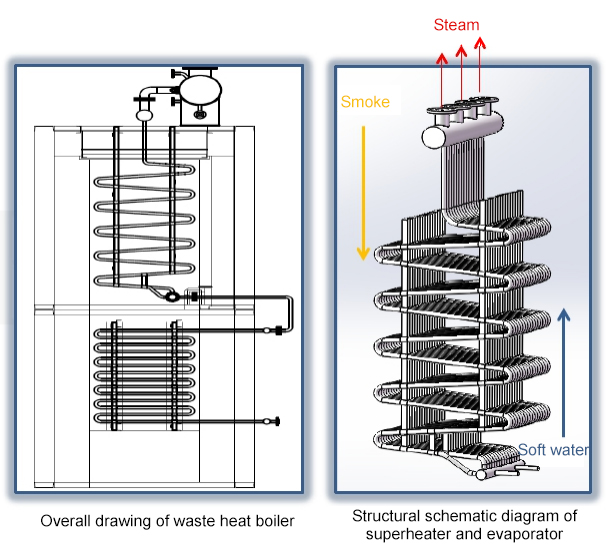

8. FTL quench system

Mainly composed of waste heat boiler, from the combustion zone to the low temperature zone are respectively evaporator, superheater and economizer system, S-type flue design, increase the quenching area, ensure that the flue gas is rapidly reduced from 800℃ to 250℃, and eliminate dioxin British rebirth conditions.

Function Description

The quenching system is mainly composed of waste heat boiler, from high temperature area to low temperature area are evaporator, superheater and economizer respectively.

(1) This system is an open system, the steam is connected to the atmosphere, and the water consumption per hour is about 0.5t

(2) The flue gas temperature can be controlled by the water volume and flow rate to ensure the temperature requirements of the subsequent flue gas treatment system

(3) Reduce the temperature from 850°C to 250°C in a short time to achieve rapid cooling of the flue gas and reduce the re-generation of dioxin

9. Condensing system

Balanced evaporative condensate separator is a key part of the furnace operation, its function:

(1) Collect water vapor generated by garbage drying and carry out gas-liquid separation;

(2) The separated organic waste gas enters the furnace and burns again;

(3) Reduce the moisture content of garbage and improve subsequent combustion efficiency;

(4) A small amount of condensed water is used for dust reduction and cooling of slag;

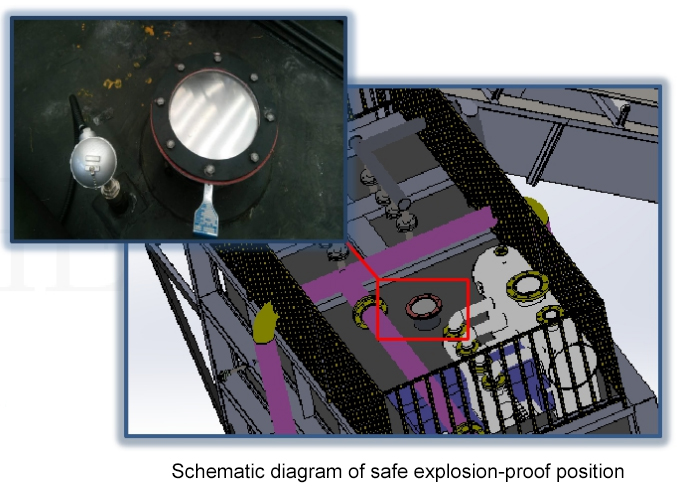

10. Security system

On the top of the gasification combustion furnace, a safety explosion-proof system is designed to ensure that the gasification combustion furnace can achieve safety during the overall operation. When the furnace pressure exceeds 0.1 MPa, the safety system will automatically unload the explosion.

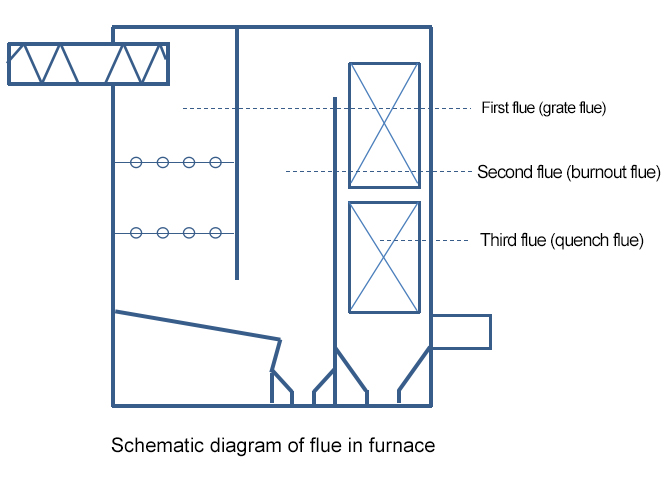

11. Flue subsystem

The flue subsystem adopts an S-shaped flue design inside the furnace body, which can ensure the residence time of the flue gas in the high temperature zone and increase the quenching area of the flue gas, improve the quenching efficiency, and achieve a compact structure and reduce the volume of the equipment. The details are as follows: The grate flue completes the process of steaming and carbonization of garbage. Reasonably design the grate spacing in the flue to improve the coordination of the grate; set up a burner in the burn-out flue to complete the “initial purification” of the flue gas, and at the same time ensure that the flue gas stays in the range of 850℃ for 4s; place waste heat in the quench flue flue The boiler rapidly cools the flue gas and crosses the dioxin regeneration temperature range; the flow rate is reduced, and large particles of dust can be settled.

12. Automatic control system

The automatic control system has a flexible and high-speed data transmission channel, so that the on-site collected signals can be displayed on the host computer in high-speed and real-time, and the control signals can be transmitted to the on-site execution unit in high-speed and real-time. The system has good real-time performance and strong anti-interference ability. The system structure is a hierarchical, fully distributed, and fully open system, which not only facilitates the expansion of functions and hardware, but also fully protects application resources and investment. It adopts distributed, software modular and structured design, so that the system can adapt to increased functions and Scale expansion and self-diagnosis.

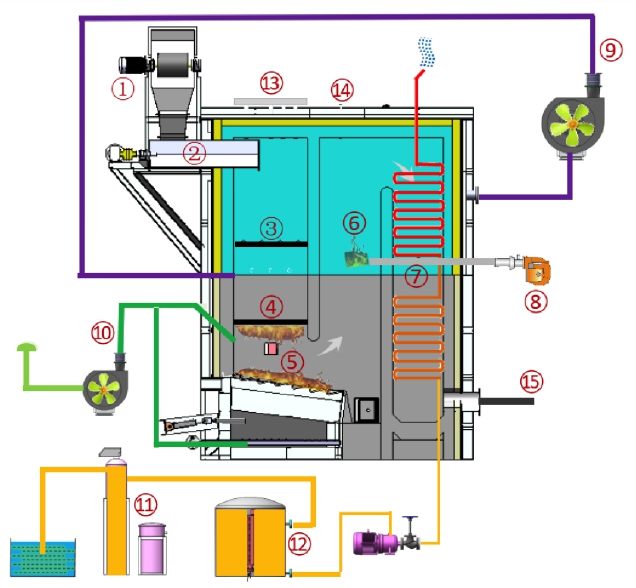

| FTL main functional area introduction 1 drop hopper 2 spiral feed 3 drying grate 4 carbonization gasification combustion grate 5 burned out burning grate 6 Fume combustion second combustion chamber 7 Waste Heat Boiler 8 spare burner 9 flue gas circulation system 10 Air supply system 11 water softener 12 water tank 13 steam collection and condensation 14 Safety System 15 connected to induced draft fan (flue gas purification system) The domestic waste gasification and carbonization complementary combustion furnace adopts the domestic waste pyrolysis and gasification process. In the high temperature and oxygen-deficient environment in the furnace, the domestic waste produces vapors and carbonized products through pyrolysis, and realizes the domestic waste through the indirect combustion of the pyrolysis products. Reduction and harmlessness. |